Electro sensors, 4-20 mA Slide Gate & Valve Position Sensors, Electro sensors Việt Nam

Nhà cung cấp: Pisteco Việt Nam

Hãng sản xuất: Electro Sensors

SG1000A

Slide Gate Monitor

Features

- Accurate gate position feedback

- Ideal for product proportioning

- No bracket required - easily mounts to gate drive shaft

- Works with either electrically or manually driven gates

- Retains gate position in the event of a power loss

- Interface with PLC or use the optional PM500 Process Meter as a remote display unit

- Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000A slide gate monitor is a complete monitoring system housed in a compact and rugged explosion proof enclosure. It provides independent, accurate feedback of slide gate position to a controller (PLC) or Electro-Sensors' optional remote display.

The SG1000A mounts directly to the end of the slide gate drive shaft and is easily calibrated with a single push button for setting the fully open and fully closed limit points of the gate. A second directional switch (clockwise/counterclockwise) enables the user to mount the SG1000A on either side of the gate. As the drive shaft rotates, the SG1000A senses the rotation and transmits a 4-20 mA signal to an external device such as a PLC or optional remote display.

SG1000B

SG1000B Position Monitor

Features

- Works on rack and pinion or linear driven gates

- Ideal for product proportioning

- Precisely measures repetitive linear movement

- Retains gate position in the event of a power loss

- Interface with PLC or use the optional PM500 Process Meter as a remote display unit

- Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000B position monitor is designed to sense the position of both linear and rack-and-pinion driven slide gates. Housed in an explosion-proof enclosure, the SG1000B is typically used to measure the position of a process that has a repetitive linear movement, providing independent and accurate feedback via a 4-20 mA signal. To achieve this measurement the SG1000B uses a telescopic-arm to convert linear movement into an angular movement and measures the arm's angle to determine the process's linear position.

SG1000C

Single-Turn Position Monitor

Features

• Shaft position feedback — 0° to 359°

• Precisely measures repetitive single

turn rotary movement

• Works on powered or manually driven shafts

• Non-volatile memory — retains shaft position

in the event of a power loss

• Interface with PLC or use the optional PM500 Process

Meter as a remote display unit

• Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000C is housed in a compact and rugged explosion-proof, NEMA 4X enclosure, the SG1000C is an encoder-based position sensor providing a 4-20 mA output and is used to measure processes that have a repetitive single turn clockwise or counterclockwise rotary movement.

SG1000D

SG1000D Valve Position Monitor

Features

- Valve position feedback — 0° up to 359°

- Precisely measures valve shaft rotary movement

- Works on powered or manually driven valve shafts

- Retains valve position in the event of a power loss

- Interface with PLC or use the optional PM500 Process Meter as a remote display unit

- Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000D valve position monitor is a complete position monitoring system housed in a compact and explosion proof enclosure. The SG1000D is an encoder-based position sensor providing a 4-20 mA output and is used to measure a rotary process such as a valve position having a clockwise or counter-clockwise rotary movement. The SG1000D works on rotary processes having a full-scale sweep as small as 15 degrees (fully-closed to fully-open), up through those having a full-scale sweep as large as 359 degrees.

SG1000E

Sub-Turn Shaft Monitor

SG1000E Features

- Accurate position feedback — 0° up to 130°

- Precisely measures shaft rotary movement

- Works on powered or manually driven shafts

- Non-volatile memory — retains shaft position in the event of a power loss

- Interface with PLC or use the optional PM500 Process Meter as a remote display unit

- Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000E Sub-Turn Shaft Position Monitor is a compact and explosion-proof system. It is an encoder-based position sensor that provides a 4-20 mA output and is used to measure a rotary process such as a shaft position having a clockwise or counterclockwise rotary movement. The SG1000E works on rotary processes having a full-scale sweep as small as 5.6 degrees (fully-closed to fully-open), up through those having a full-scale sweep as large as 130 degrees.

SG1000F

Two-Turn Shaft Monitor

Features

- Best accuracy for two-turn maximum shaft angle (rotational) position

- Translates shaft position to 4-20 mA output

- Configurable measurement range (0-1/12 turn to 0-2 turns)

- Direct shaft attachment (3/8-16 UNC)

- Applications include electrically /manually-driven rack-and-pinion gates and valves

- 24 VDC ±10% powered

- Cast aluminum explosion proof (XP) housing

- UL Listed Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000F two-turn shaft monitor is a complete monitoring system housed in a compact and rugged explosion proof enclosure. It provides independent, accurate feedback of slide gate position to a controller (PLC) or Electro-Sensors' optional remote display.

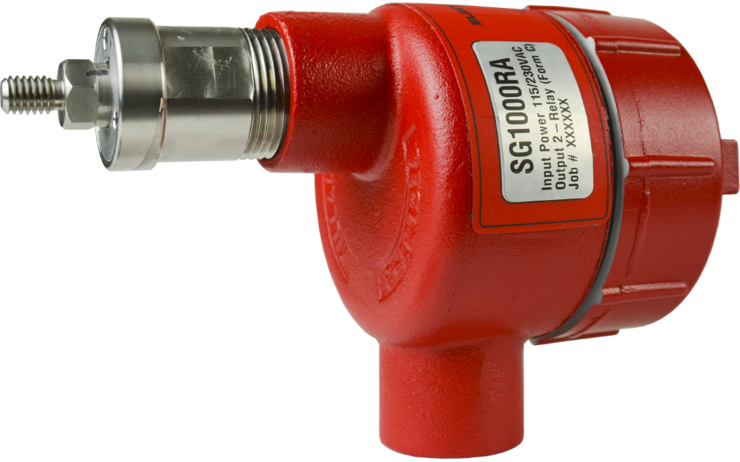

SG1000RA

Slide Gate Monitor With Relay Output

Features

- Monitors a slide-gate's fully-open and fully-closed positions

- Open/closed positions indicated via 2-Relay output

- Accurate gate position feedback

- No bracket required - easily mounts to gate drive shaft

- Retains gate position in the event of a power loss

- Replacement for end-point limit switches

- 115 - 230VAC ±10% (50-60 Hz) powered

- Cast aluminum explosion proof (XP) housing

- Class I, Div I (C, D) Class II, Div I (E, F, G)

The SG1000RA slide gate monitor is designed to be an independent option for those seeking to monitor gate end-point positioning or equipment. Once set points are established the SG1000RA can command equipment with built-in relay outputs. The SG1000RA is designed to work independently from a plant control system.

PM500

Two Analog Input Process Meter

- 4-digit display switchable between two inputs

- Completely field programmable

- Modbus RTU communications (RS-485)

- Optional 2 or 4 relay outputs

- Optional analog output card with (2) 4-20 mA outputs

- Full diagnostic functions

- Sensor failure detection and notification

- Built-in relay test function

- Optional explosion proof enclosure

- Optional NEMA 4X enclosure kit

- 115 VAC (50/60 Hz), with 230 VAC (50-60 Hz) power option

The PM500 is a fully programmable process meter that has two 4-20 mA sensor inputs that can be scaled to any user-selected units. The most common inputs are temperature, position, and speed. The sensor transmits the 4-20 mA signal to the PM500 via a two- or three-conductor shielded cable. The PM500 then compares this analog signal to its programmed values to determine the appropriate display value and output states. The inputs are independent of each other and can be displayed as two different processes. For example, one input could be programmed for temperature and the other for position.

Options:

- 2 or 4 programmable Form C relay contact outputs. Rated 250 VAC, 30 VDC at 5 amps resistive load

- A 2-channel, 16-bit 4-20 mA output card

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652