Schiltknecht Vietnam, Chimney Measuring System STEMO1, đại lý Schiltknecht Việt Nam

Nhà cung cấp: Pisteco Việt Nam

Hãng sản xuất: Schiltknecht

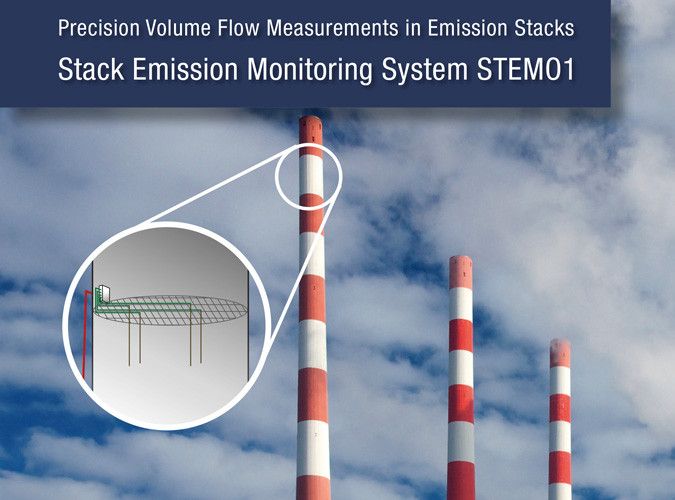

Volume flow measurement of the air volume in exhaust air stacks

The volume flow measurement is necessary in addition to the concentration measurement (e.g. % CO2/m3) to measure the exact volume of noxis gases.

This is the volume flow measurement of air in the stack so that the volume of air (in m3) that flows through the chimney cross-section per unit of time (in s or h) is to be measured.

The measuring system is installed preferably at the top of the stack where the exhaust air enters the atmosphere. The STEMO1 stack monitoring system provides a high-precision volume flow measuring instrument the measuring uncertainty of which can be reduced to considerably below 1 %. Its accuracy is “traceable”, i.e. EN ISO 15267 and the new edition of the EN ISO 14181 standard are optimally satisfied. The necessary approval procedures are being prepared.

- Robust, weather-proof sensor mechanics without moving parts

- Grid measurement of the volume flow with a high accuracy of under 1 %

- Simple installation for continuous use

- Can also be used as a mobile unit

Function Principle:

The measurement is a net measurement (grid measurement) in accordance with VDI regulation 2640. At a sufficient inlet distance of >10D (D = internal diameter of stack) high accuracy is possible with 4 to 8 measuring points. This accuracy is based on our calibration systems for the parameters air-flow velocity and micro pressure for which we are accredited in accordance with EN ISO 17 025 by the authorities.

The drawing shows four grid points with Prandtl (or pitot) tubes which are exposed to the air flow from bottom to top. It is remarkable that flows between 0.3 and 20 m/s can be measured with the method described.

The four measured values from the four grid points are averaged and converted into the unit of volume flow (m3/h). The prerequisite for this is that the inner diameter of the stack is known

The remote field measuring transducer sends its measured data digitally (RS 485) to the central unit which is accommodated preferably in the control room.

STEMO1 volume flow measuring systems are designed especially for use stacks. They can be installed with little effort or can be mounted as mobile units on the stack crown. Only robust, stainless steel mechanical sensors are found inside the stack, the evaluation electronics are accommodated in the field measuring transducer and in the separate control room. A certificate is available for the necessary lightning protection measures.

The measuring system is already in operation in a nuclear power plant in Switzerland.

Components:

Technical Data:

Important Technical Data:

4 – 8 Prandtl tubes per measuring point, arranged in grid form

| Measuring ranges: | 0 ... 10 m/s 0 ... 15 m/s 0 ... 20 m/s |

| Accuracy | <0,1 m/s |

| Outputs | 4 ... 20 mA for the parameters:

|

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652