Electro sensors Vietnam, shaft speed pulse generators Electro sensors Vietnam

Nhà cung cấp: Pisteco Việt Nam

Hãng sản xuất: Electro Sensors

ENCODERS

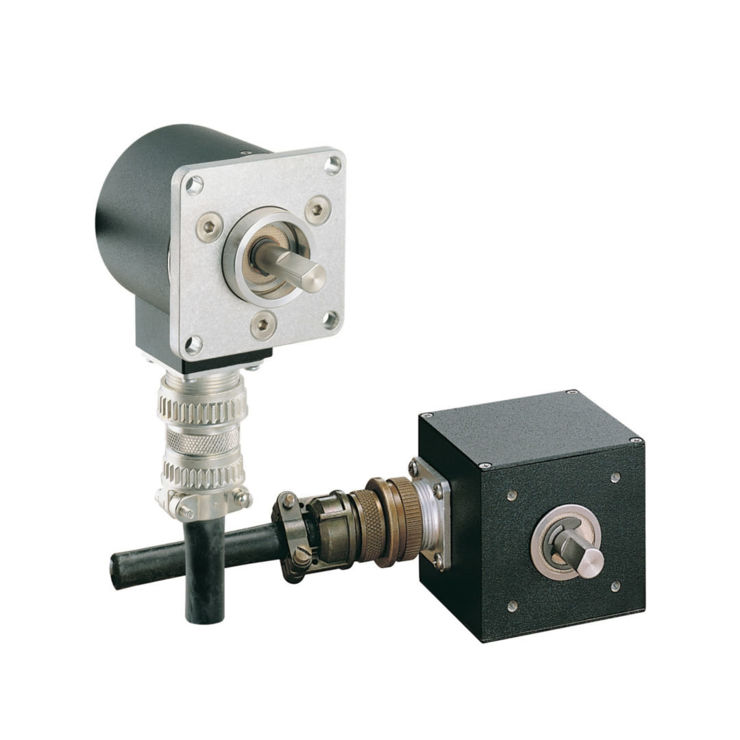

#380 and #470 Rotary Shaft Encoders

Features

• Ideal for use on slow speed applications

• Multiple mounting configurations for easy installation

• Wide variety of pulse per revolution counts

• Traction wheel assembly available

The #380 Encoder is a standard industrial grade encoder available with single channel or quadrature output. The #470 Encoder has a size 25 heavy-duty industrial housing with rugged sealed ball bearings and an anti-backlash flexible shaft coupling to isolate the internal high precision encoder from both axial and radial shaft loading. The #470 Encoder supplies a quadrature output with an index pulse, and optional line driver output.

Rotary Shaft Encoders are ideal for use on any rotating shaft to provide a digital output signal to tachometers, counters, speed switches, motor controls, or anything requiring a pulse input. Flexible shaft couplings are available as an option to compensate for shaft misalignment, and are recommended for most applications.

Rotary Shaft Encoders convert shaft rotation into square wave output pulses. They provide an accurate means of transmitting actual speed information for detecting rate, position, or direction of rotation. The shaft encoder produces an output signal by rotating a disc with clear and opaque segments between a light emitting diode and a photo-transistor sensor. The output signal from the encoder is then converted into a square wave signal by an internal squaring circuit. The number of output pulses per shaft revolution is determined by the number of clear and opaque segments on the disc. Quadrature (bi-directional) models have a second LED and sensor positioned 90-degrees apart to produce two square wave signals.

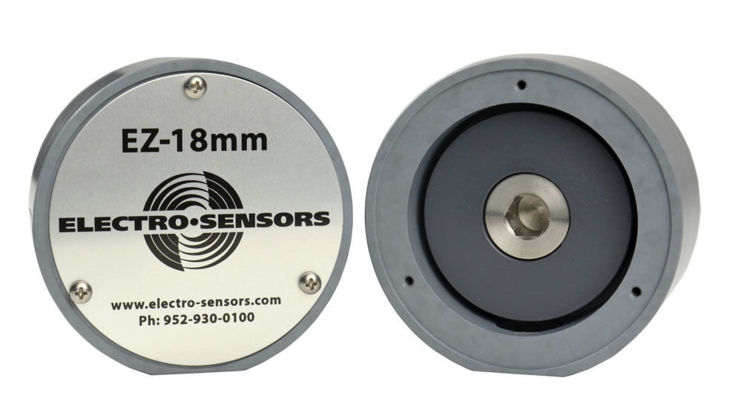

EZ-3/4IN & EZ-18MM

EZ Mounting for Speed Sensors

Features

• Mounts directly to the tapped shaft

• Can be used with optional Mounting Magnet

if shaft is not tapped

• Pulser disc is included

• EZ-3/4in is for the 906, 916A, and 932 sensors

• EZ-18mm is for Series 18, ST420 Series,

and SpeedTalker DN-BH

The EZ-18mm and the EZ-3/4in Easy Mount Bracket Assemblies are used with Electro-Sensors speed sensors to generate pulses or 4-20 mA signals for use with display meters, speed switches, or PLC inputs. The EZ-18mm and EZ-3/4in mount directly to the shaft so no other mounting brackets are needed. A securing strap is also provided.

EZ-3/4in with 906 Speed Sensor installed on a tapped shaft

EZ-18mm with Series 18 Speed Sensor installed. Shown with the cover removed, exposing the 8 PPR Pulser Disc within the housing. Every Mounting Assembly comes with a Safety Strap.

Mounting Magnet Option for Untapped Shafts

EZ-3/4in with 906 Speed Sensor installed on an untapped shaft utilizing an

MM-1.25 Electro-Sensors Mounting Magnet Option

EZ-100 & EZ-SCP

EZ-100 Mounting Bracket

Features

• New and retrofit installations

• Easy and fast installation (drill and tap)

• No extra brackets or hardware required

• 1/2 inch - 13 UNC 2A thread

• Includes 255-EZ Pulser Disc (other EZ Pulser Disc

models available)

• Rated for use up to 300 rpm (for information about

use with higher speeds, consult factory)

Can be used with the following shaft speed switches and sensors:

• 907 XP

• M100

• M100T

• FB420

• SpeedTalker DN-XP

EZ-SCP Mounting Bracket

Features

• New and retrofit installations

• Easy and fast installation (drill and tap)

• No extra brackets or hardware required

• 1/2 inch - 13 UNC 2A thread

• Includes 255-EZ Pulser Disc (other EZ Pulser Disc

models available)

• Rated for use up to 300 rpm (for information about

use with higher speeds, consult factory)

Can be used with the following shaft speed switches:

• SCP1000 / SCP2000

MAGNET WHEELS

199SM / 198EM Magnet Wheels

Features

• Use with 1101/1201/1202 Hall Effect and 1102

Magnetoresistive shaft speed sensors

• 60 pole pairs (Hall Effect)

• 120 alternating magnets (Magnetoresistive)

• Non-contact sensing

• End-of-shaft (198EM) or over-shaft (199SM

models) mounting

• NEMA C Ring Kit compatible

• 10,000 rpm maximum speed

The 199SM (Shaft Mount) and 198EM (End Mount) Magnet Wheels comprise a ferro-magnetic nylon ring with 120 alternating magnetic poles and an aluminum hub (available without aluminum hub). The wheel is 3.75" in diameter with the magnetic surface on the outside circumference of the wheel. The magnets are rectangular and evenly spaced between non magnetized spaces. The wheel is typically mounted on a shaft up to 3" in diameter.

Our shaft mount wheels are custom-bored to slide snugly onto the shaft, and are then secured with two set screws. Many standard hub sizes are in stock, including common NEMA C Frame Motor sizes. These magnetic wheels are compatible with Electro-Sensors' Hall Effect and Magnetoresistive sensors.

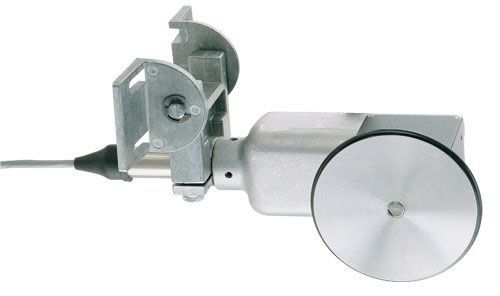

TRACTION WHEELS

Traction Wheel Encoder Assembly

Features

- A complete ready-to-install system

- 1 to 1,270 pulses per revolution

- Optional Bi-Directional models

- Double traction wheel assembly

- Specify pulses per revolution when ordering

The Traction Wheel Encoder Assembly consists of a rotary shaft encoder, the traction wheel, the mounting bracket hinge clamp assembly, and the mating connector. There are three models of traction wheels: black neoprene rubber, smooth polyurethane, and diamond knurled aluminum tread.

The traction wheel rides directly on the material being monitored and is ideal for slow speed applications. The wheel is connected to a rotary shaft encoder, which is supported by the mounting bracket. The encoder then generates a digital pulse frequency based on the number of pulses per revolution and the speed of the traction wheel. This digital signal is sent via the mating connector to a counter, ratemeter, or other control equipment

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652