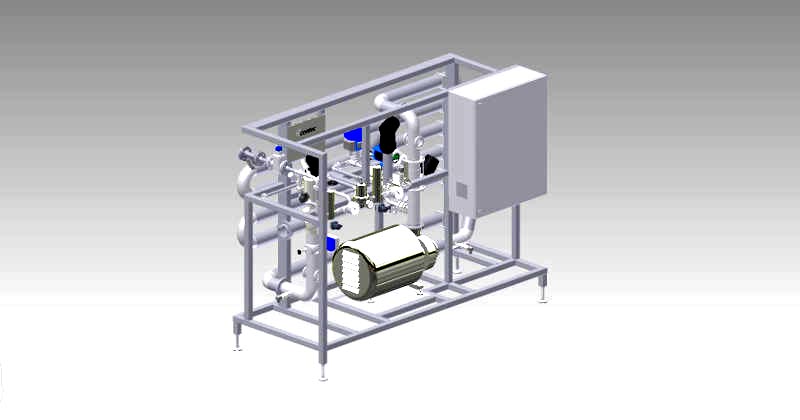

Wort Aerator

Application

The Wort Aerator is used for the continuous and highly accurate injection of oxygen or sterile air into beer wort. For yeast reproduction and growth and consistent fermentation, the specified oxygen content needs to be exactly reached.

Description

The solubility of oxygen in wort depends on the temperature. The colder the liquid, the better is the oxygen solubility. Therefore, aeration is done after cooling of the wort. The amount of oxygen or sterile air to be added to the wort depends on various factors, e. g. original gravity, type of yeast and the desired final product characteristics. The Wort Aerator can be designed for manual or fully automated operation. Automated systems measure and control the O2 content of the wort with highest precision with an optical OXYTRANS sensor made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for O2 control. Based on oxygen and flow measurement, the amount of oxygen injected is precisely adjusted to match the measured wort flow. For O2 injection the Wort Aerator has a specifically designed Vortex-Venturi injector that feeds oxygen in a very large number of very fine bubbles directly into the product stream. Due to pressure and turbulent flow, the oxygen dissolves completely and absolutely homogeneously in a very short time. At the end of the dissolving path a control valve can be installed to keep the pressure in the system constant and above the saturation pressure. The Wort Aerator is equipped with a sterile filter system to sterilize the incoming gas.

- High precision OXYTRANS sensor for process control

- Specifically designed Vortex-Venturi injector for gas injection

- Customized modular design with standard PLC

- Skid mounted for easy installation and start-up

- Hygienic execution and full CIP capability

Typical Technical Data

| Capacity | 10 - 3.000 hl/h |

| Dosing Range O2 | 8 - 40 ppm |

| Material | according to requirements (1.4301/AISI 304, 1.4404/AISI 316L, …) |

| Options | different automation levels; remote maintenance access; in-line O2 measurement; booster pump; wort cooler; yeast pitching |

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652