Electro sensors, Wireless hazard Monitoring Electro sensors, thiết bị giám sát không dây cho môi trường khắc nghiệt, Electro sensors Việt Nam

Nhà cung cấp: Pisteco Việt Nam

Hãng sản xuất: Electro Sensors

HAZARDPRO™ SYSTEM

Wireless Hazard Monitoring System

• Field-proven reliability

• ETL approved Class II, Div. 1 sensors, and wireless

node

• Intuitive touchscreen display

• Lowest total installed cost

• Real-time display of system data

• Battery-powered node (5+ year life)

• Quick disconnect sensors

• Built-in control relays

• Wireless communication—No Conduit

• Remote access via email, text, and web

• Continuous system self-check routines

• True multi-point ambient compensated setpoints

• User-friendly slow-down test and documentation

• Scalable—add equipment without reprogramming

• Auto-speed calibration setpoints

• Models:

XS up to 4 pieces of equipment

XM up to 16 pieces of equipment

XL up to 32 pieces of equipment

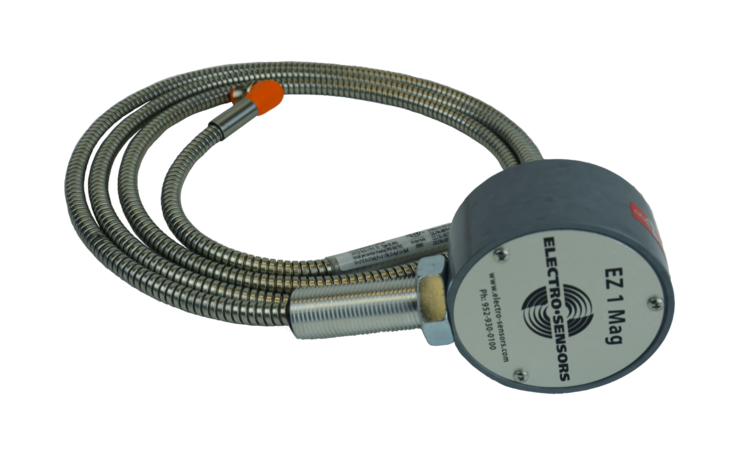

HAZARDPRO™ RPM SENSOR

HazardPRO Shaft RPM Sensor

Features

• Direct connection to HazardPRO node

• Fixed cable with M12 connector included

• 2-wire (current loop type)

• Installs using EZ 1 Mag bracket assembly

• Optional mounting magnet

• Optional stainless steel jacketed cable

• Class II, Div 1, Groups E, F, G, Class III, Div 1

The shaft RPM sensor is typically mounted to the tail shaft of the machine being monitored. The sensor is mounted in the EZ 1 Mag mounting bracket assembly, which attaches to the tail shaft with a 1/2"-13 UNC tapped hole.

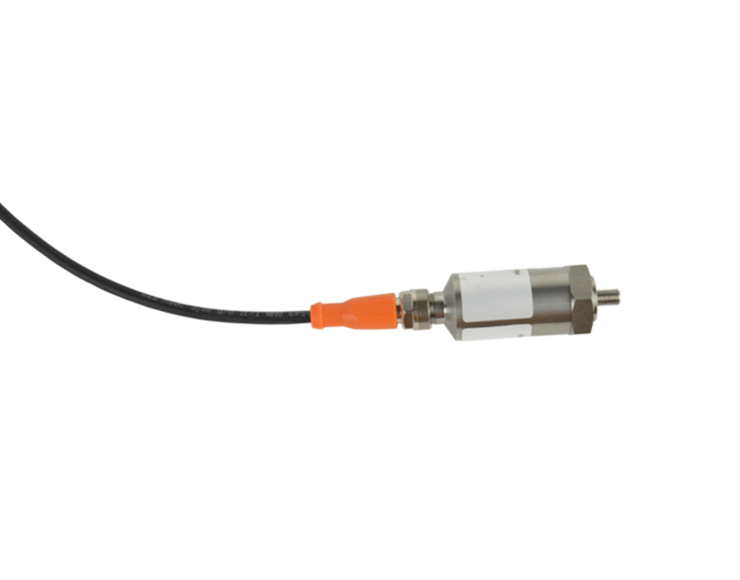

HAZARDPRO™ BEARING SENSOR

HazardPRO Bearing Temperature Sensor

Features

• Direct connection to HazardPRO node

• Fixed cable with M12 connector included

• 2-wire (current loop type)

• Installs in bearing zerk or thermowell

• Probe lengths available 2", 4", 6", 10"

• Optional stainless steel jacketed cable

• Class II, Div 1, Groups E, F, G, Class III, Div 1

1/4" stainless steel probe is used with bearings, thermowells, and compression fitting mounts on tanks and piping. Available with or without compression fitting adapters.

HAZARDPRO™ VIBRATION SENSOR

HazardPRO Vibration Velocity Sensor

Features

- Protects equipment against unwanted vibration

- Measures in RMS (per ISO 10816)

- NEMA 4X enclosure

- 1/4-28 UNF 2A threaded mount

- M12 connector

The HazardPRO vibration sensor or VTHP is an accurate RMS vibration velocity sensor that measures and checks for unwanted equipment vibration. If a piece of equipment is vibrating outside of its normal setpoint range a critical failure could be imminent. This vibration sensor or VTHP acts as a preventive maintenance measure while communicating live sensor data directly to a HazardPRO System Manager or plant control system. The robust sensor comes with a stainless steel NEMA 4X enclosure, 1/4-28 mounting stud, and an M12 connector.

Mr. Hà

Mr. Hà live:ha_1652

live:ha_1652